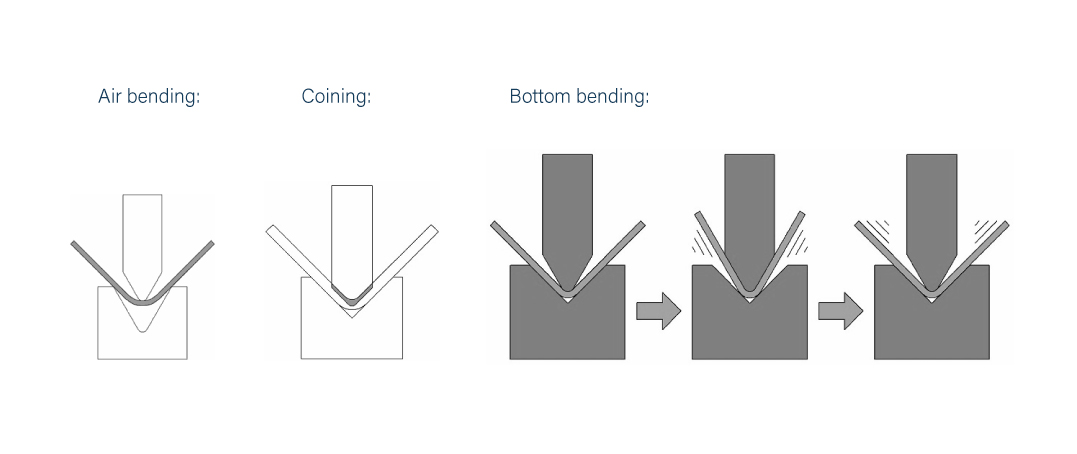

Air bending is the most common type of bending process used in sheet metal in this process the work piece is only in contact with the edge of the die and the tip of the punch the benefits of air bending are as following.

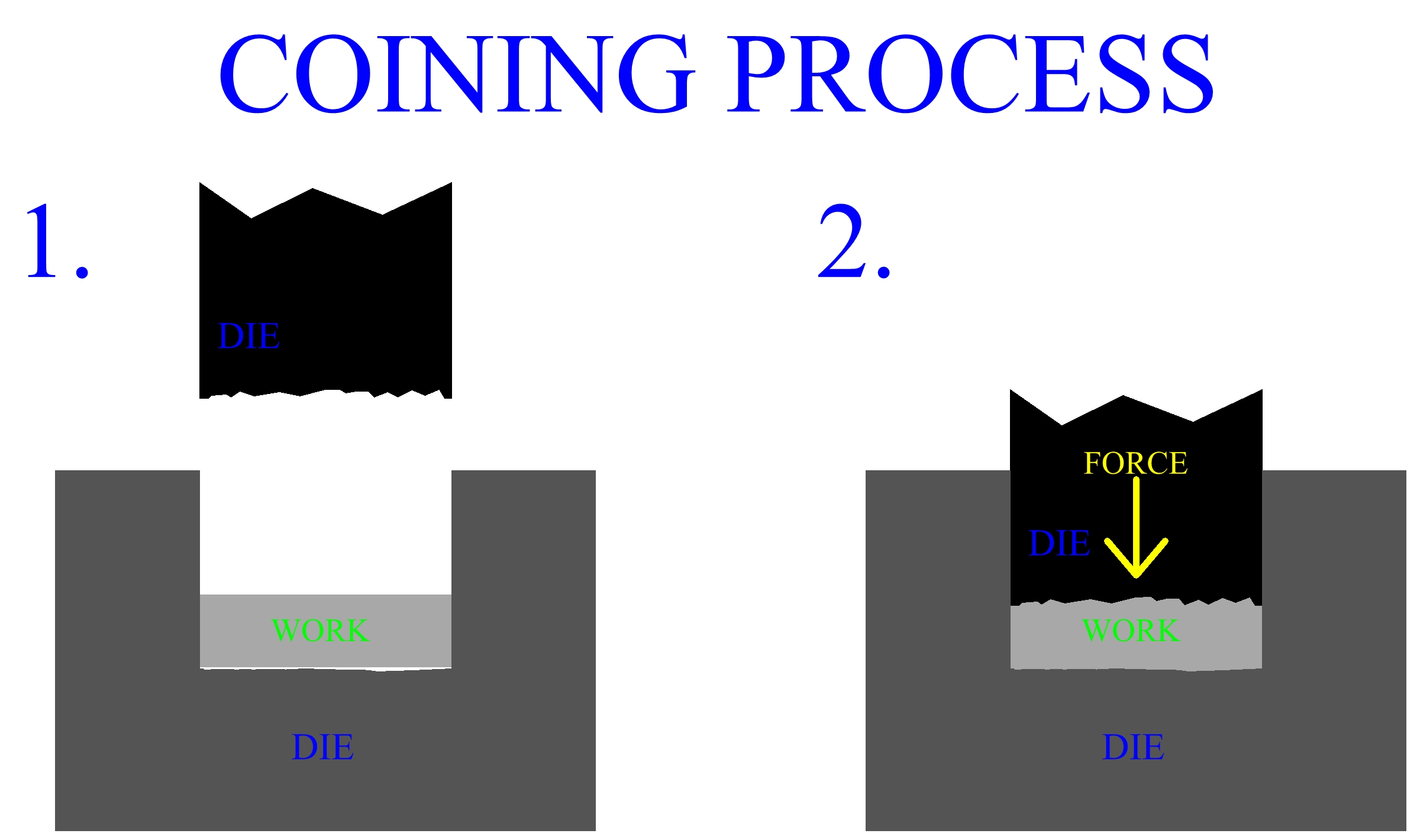

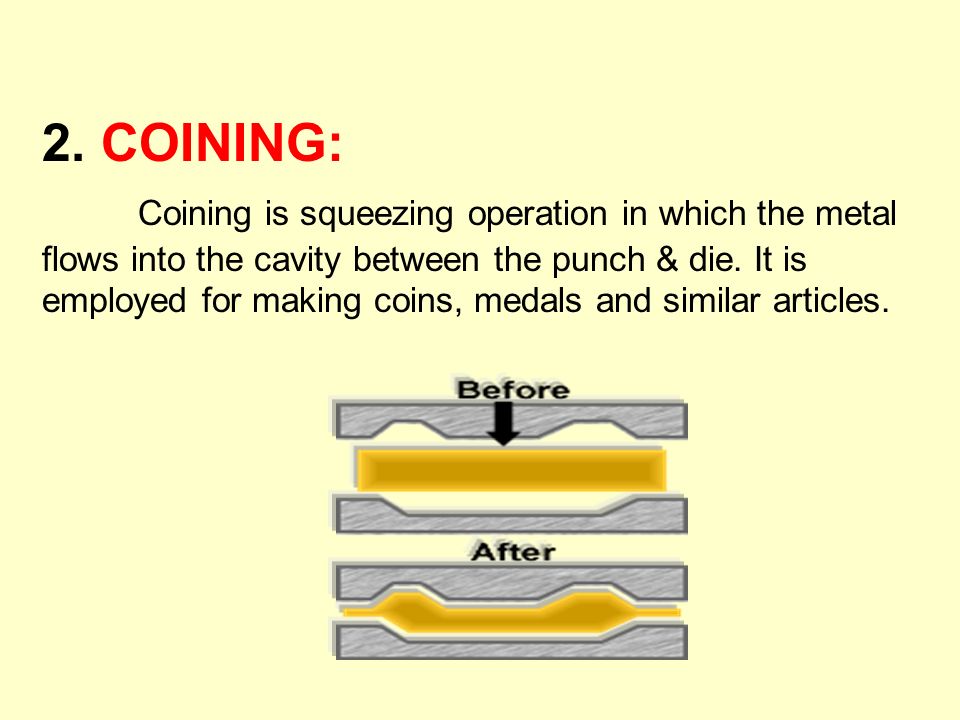

Coining process in sheet metal.

As a result of the high deformative stress the metal conforms to the shape of the die.

Coining dies create the part s shape by squeezing the metal under extreme pressure.

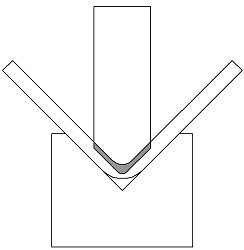

In this process the die angle should match the intended.

Benefits cnc controlled process with correction option slotting operations in individual steps.

Because the sheet metal flows during the process of coining the bend radius formed by coining is always equal to that of the punch tip.

Bottom bending has similarities to both air bending and coining.

Metal coining is often a finishing process for manufactured products.

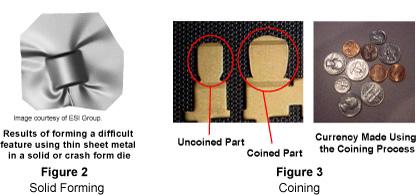

Coining may be used to control surface quality and detail on parts.

Coining also can reduce the metal thickness.

Coins metal currency are created with the coining process.

The coining process is preferred when there is a high tonnage.

A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it see figure 3.

A beneficial feature is that in some metals the plastic flow reduces surface grain size and work hardens the surface while the material deeper in the part retains its toughness and ductility the term comes from the initial use of the.

Commonly used equipment include box and pan brakes brake presses and other specialized machine presses typical products that are made like this are boxes such as electrical enclosures and rectangular ductwork.

Techniques of coining completely closed dies are used for this process.

Coining is a form of precision stamping in which a workpiece is subjected to a sufficiently high stress to induce plastic flow on the surface of the material.

Metal rolling metal extrusion metal drawing sheet metal powder processes metal coining metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece.

Coin production figure 8 1 indenting impressions into badges coining components for mechanical engineering and the electrical engineering industry figure 8 2.

Slotting coining forming sheet metal.

High pressure is applied on the closed die containing the metal work piece.

During the coining process the material is put under enough pressure that the punch tip penetrates the material at the bottom of the bend and it begins to flow into the die.

The grob slotting technology is a universal and extremely cost effective slotting coining and forming process for cup or ring shaped sheet metal workpieces.