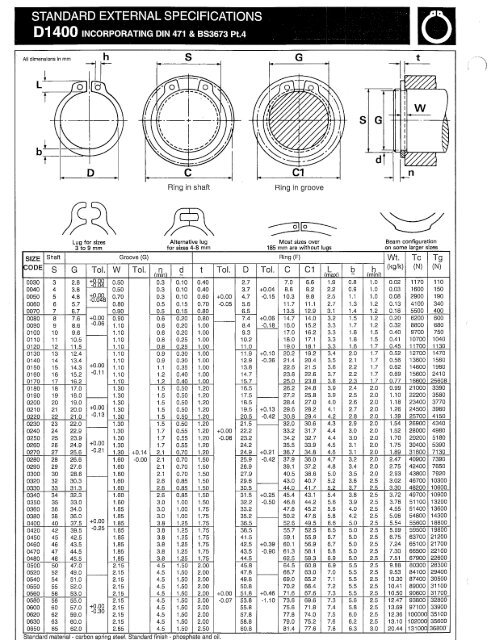

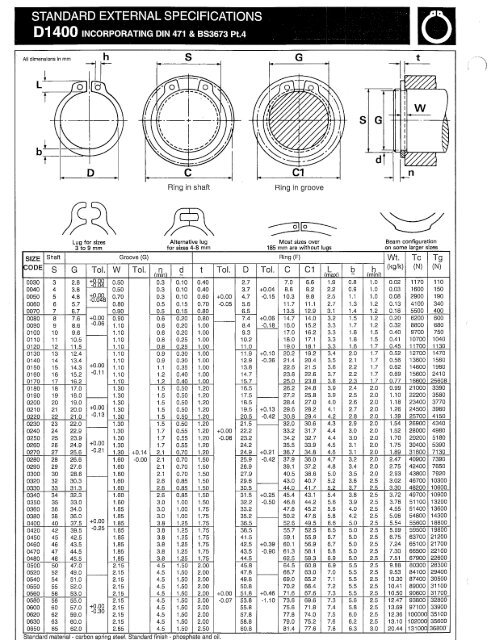

External snap rings to din 7993.

External snap ring groove dimensions.

For most plated rings the maximum ring thickness will not exceed the minimum groove width s minus 0 0002 inch.

Partnumber application diameter b in groove diameter g in groove width w in groove depth in ring diameter d in ring thickness t in ring.

Ansi inch retaining rings external.

Internal snap rings to din 7993.

Groove diameter width g inch total inch total inch w inch 002 000 003 000 003 000 004 000.

External retaining rings also known as external snap rings sit in the grooves on the exterior of shafts of any size.

Includes ring and groove design data groove dimensional and tolerance information.

See below for our entire list of external retaining ring dimensions and configuration drawings.

Basic metric size retaining snap rings per.

If you do not see a ring that meets your specs you.

Full range available to size 10 inches 125 to 10 00 standard material 12 to 20 beryllium cooper 25 up carbon spring steel.

Industrial retaining snap rings 3100 series.

Rotor clip is the manufacturer of retaining rings snap rings circlips wave springs single turn wave springs multi turn wave springs spiral rings non threaded fasteners pliers dispensers applicators hose clamps axial rings radial rings self locking rings constant section ring metric rings din rings ansi ring jis ring band clamps gateway page with links to facilities in the.

Thickness indicated is for unplated rings.

Ansi b27 7 size chart.

Depth of groove d od id 2.

Retaining snap ring is a fastener that holds components or assemblies onto a shaft or in a housing bore when installed in a groove.

Rolling bearings on shafts.

All dimensions are in inches.

Starlocks push on fasteners metric.

External snap rings to din 5417.

The areas of the ring that protrude out from the shaft hold it in place.

The purpose of the ring groove is to absorb the forces transmitted from the retained machine component into the seeger retaining system.

Metric external circlip dimensions are shown in the following chart according to the din 471 standard.

Groove diameter d 2 and groove depth t.

External retaining ring assortments pull these rings open with retaining ring pliers pass over the end of a shaft and release to spring into a groove.

Circlips are fitted with spring retention in grooves and are suitable for the transmission of axial forces.

As shown in figure 1 the groove is identified by the groove diameter d 2 and dependent on it by the groove depth t and the groove width m.