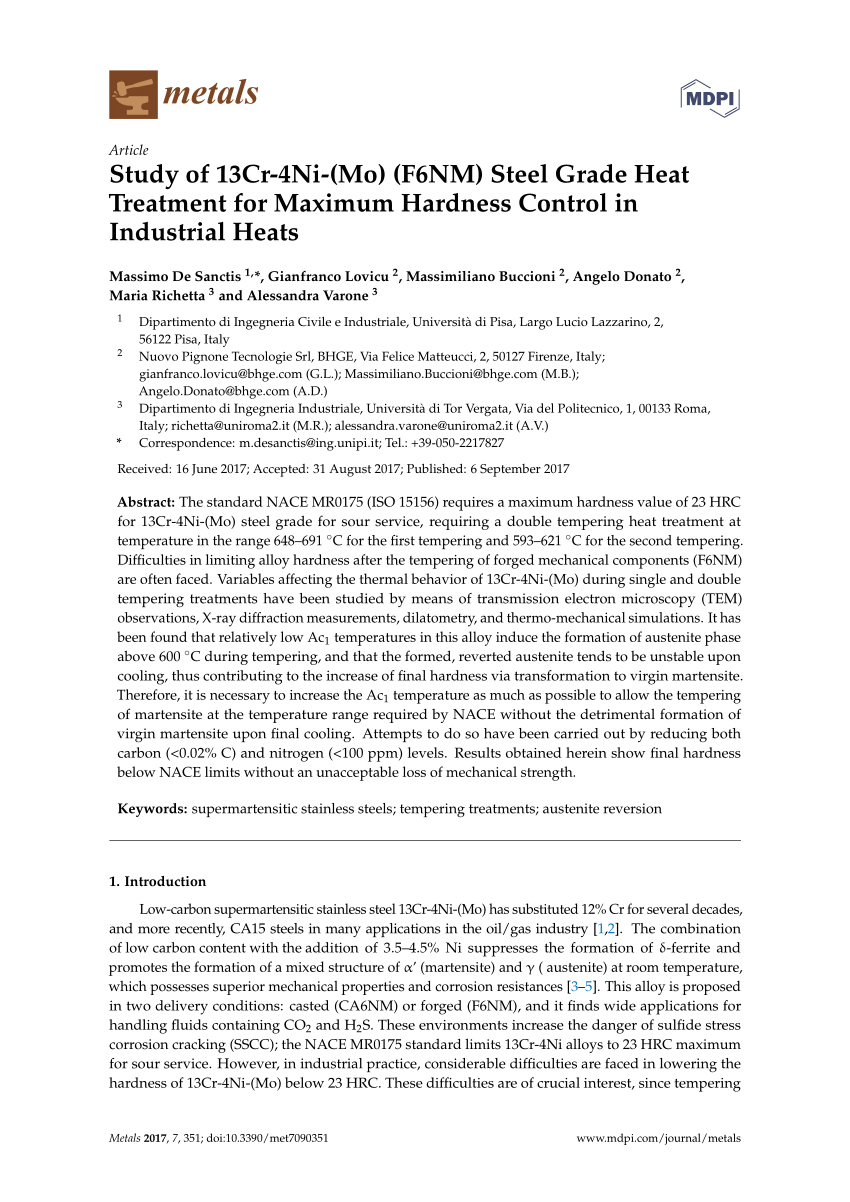

Astm a182 gr f6nm datasheet astm a182 gr f6nm mechanical properties chemical element astm a182 gr f6nm technical specifications of astm a182 gr f6nm steel material properties.

F6nm stainless steel data sheet.

Rather than create a new set of datasheets it has been decided to make use of the excellent datasheets which already exist.

In addition to good atmospheric corrosion resistance the alloy provides excellent resistance to corrosion or staining by many organic media in relatively mild service.

1 4542 type 630 a precipitation hardening martensitic stainless with high strength and hardness and good corrosion resistance chemical analysis weight all values are maximum unless a range is otherwise indicated chromium 15 0 min.

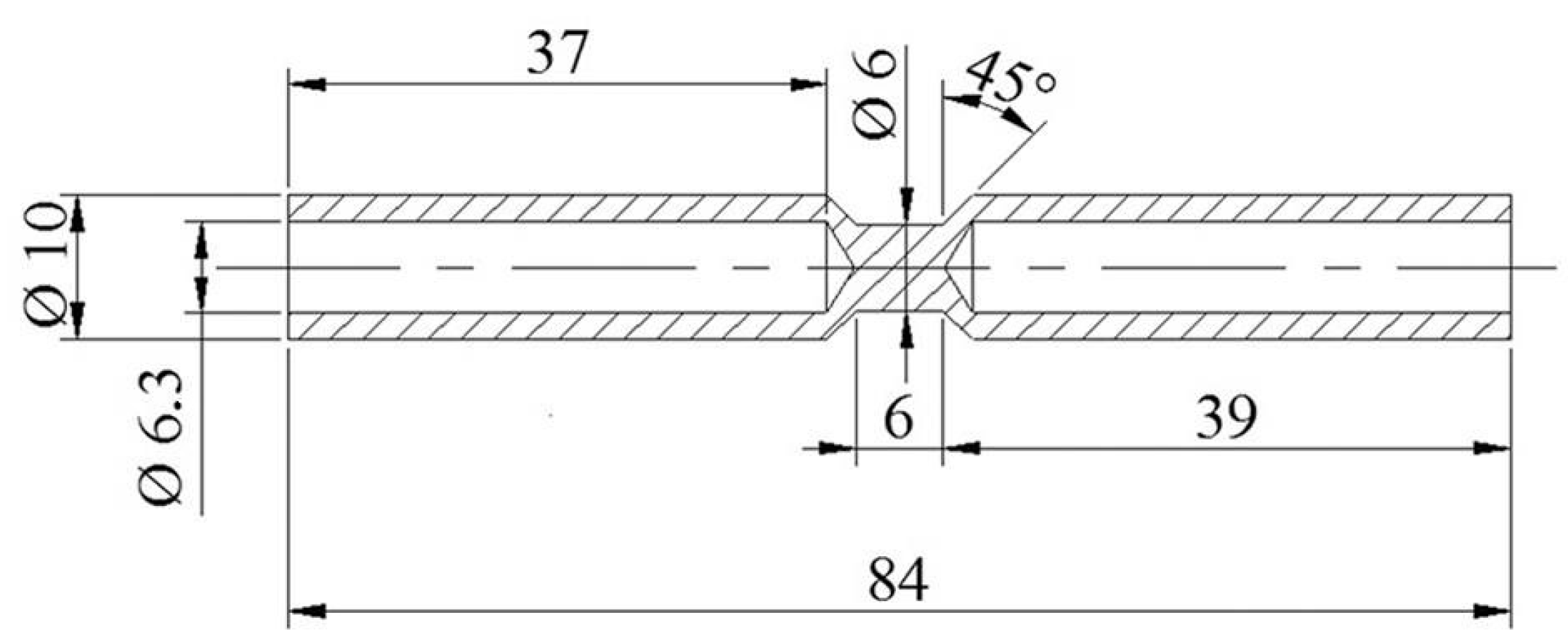

Uns s41500 steel is air hardening with little danger of thick sections cracking during heat treatment.

Phosphorus 0 04 nickel 3 0 min.

5 0 max.

The additions of nickel and molybdenum which gives it excellent sub zero notch ductility superior to other standard 13 cr 410 and 420 mod martensitic stainless steels.

Astm a182 is a martensitic stainless steel.

Austenitic stainless steels.

Alloy 17 4ph uns s17400 w.

The high toughness properties provide 1 4313 with excellent capabilities and increasing popularity.

The alloy has a high hardenability so that a wide range of hardness 144 to about 400 bhn and other mechanical.

1 4313 f6nm uns s41500 is a corrosion and acid resistant soft martensitic chromium nickel steel with added molybdenum.

Original stainless steel used for cutlery.

F6nm 2017 08 29 11 13 15 origin remark 0 click specifications grade f6nm data sheet f6nm chemical grade f6nm mechanical properties from steelmaking esr melted blooming forging hot rolling heat treatment straightening ultrasonic test cold working or machined.

The stainless steel advisory service receives requests for datasheets for individual steel grades.

Through our advanced engineering and testing capabilities we work with a range of materials.

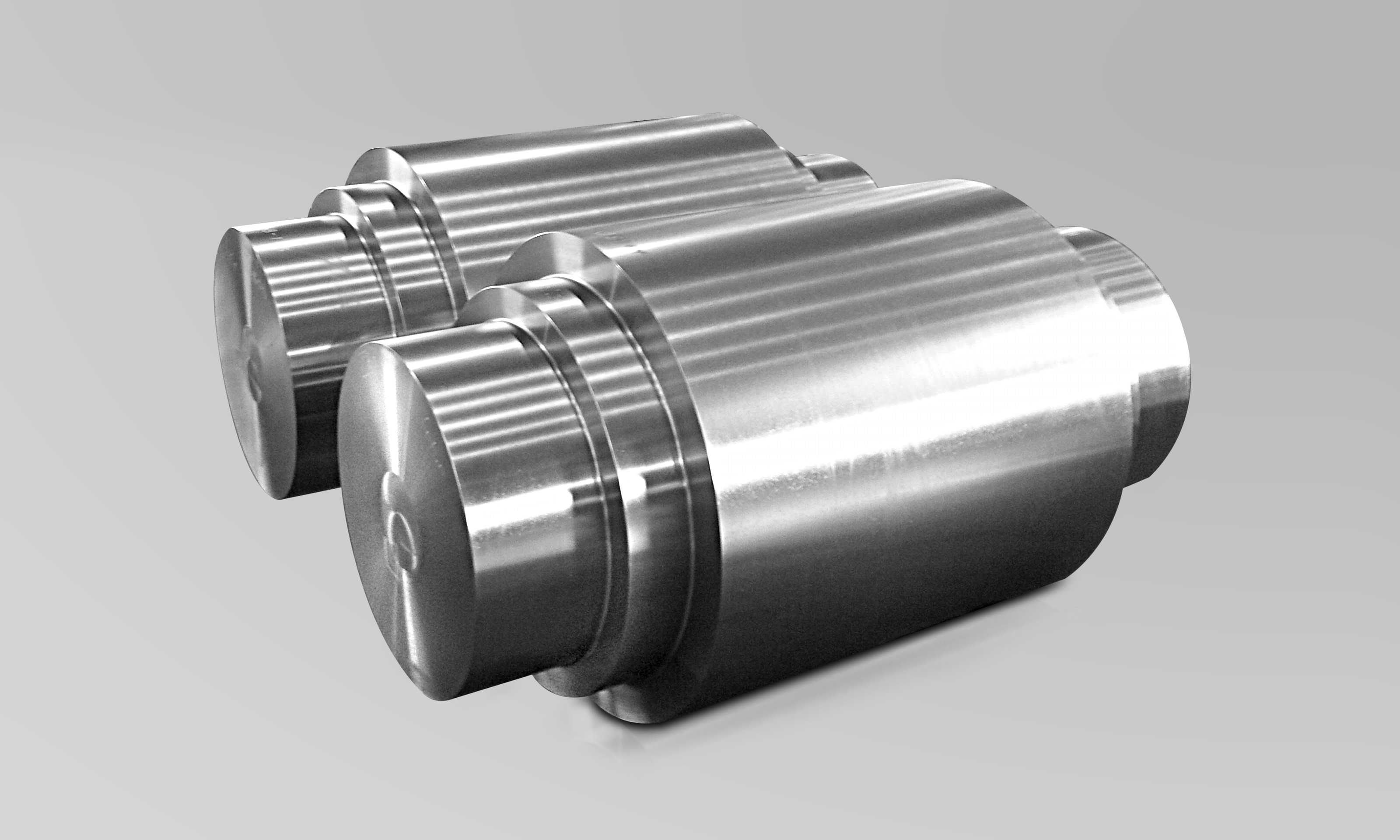

Valves compressors and centrifuges are typically made of this stainless steel.

This could be stainless steel to nickel alloys ã â â whatever your forging needs here at the abbey group we can work with an array of materials that are engineered to the highest quality.